Pre-engineered Steel Buildings (PEBs)

PEB

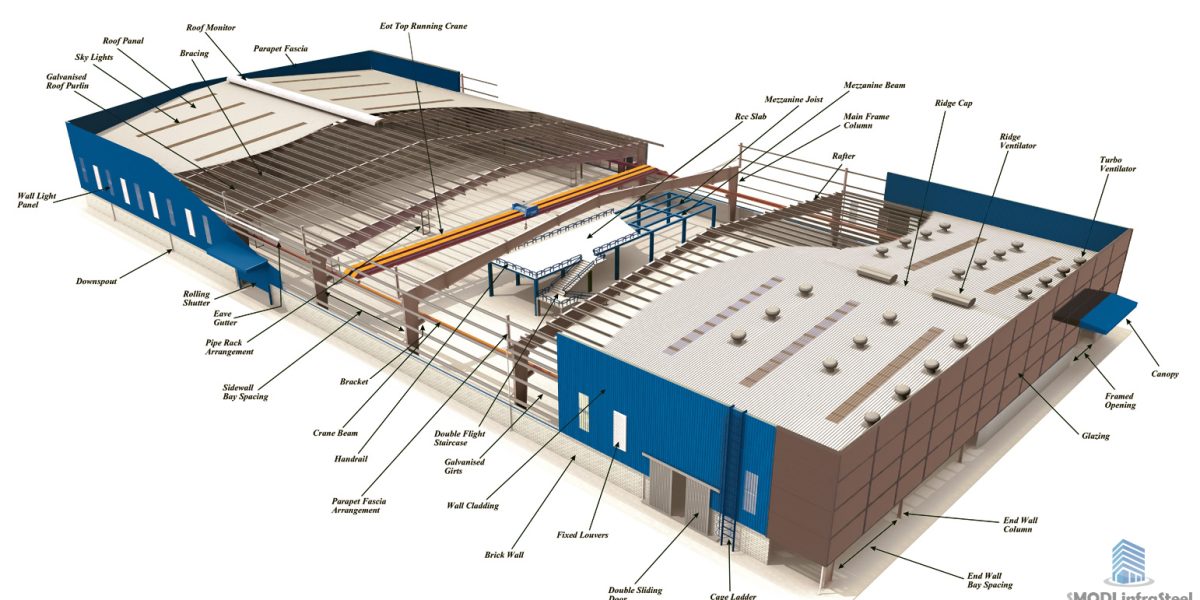

Pre-engineereing building (PEBs) are steel structures that are built utilising a variety of different building components, including main members, secondary members, roof and wall sheets linked to one another. These buildings can be fitted with a range of structural and non-structural additions, depending on the requirements of the customer, including skylights, wall lights, turbo vents, ridge ventilators, louvres, roof monitors, doors and windows, mezzanine floors, fascias, canopies, crane systems, insulation, etc. All PEB steel structures are made to order and are strong while weighing less. Hence, during the past forty years, steel building designs have improved in flexibility, toughness, and adaptability, making steel one of the most popular building materials.

Wide-span, low-rise, non-residential buildings are the perfect fit for PEBs. PEB manufacturing has a number of important benefits, including low cost, factory-regulated quality, lifespan, flexibility in extension, environmental friendliness, quicker installation, etc. There are numerous different uses for pre engineered buildings, including factories, warehouses, showrooms, supermarkets, aeroplane hangars, metro stations, offices, retail malls, schools, hospitals, community facilities and many more.

Being a top producer of PEBs, Sun Corporation offers a full range of services, including designing, fabrication, and erection, improving quality control throughout the whole process.

Pre-engineered steel buildings consist of the following components:

Pre-engineered steel buildings consist of the following components:

- Columns: These are the vertical structural members that support the weight of the building.

- Beams: These are the horizontal structural members that support the weight of the roof and floor.

- Girders: These are the long, horizontal structural members that support the weight of the roof and floor and transfer it to the columns.

- Purlins: These are the short, horizontal structural members that support the roof deck.

- Rafters: These are the inclined structural members that support the roof deck.

- Roof deck: This is the surface that the roofing material is attached to.

- Wall panels: These are the vertical structural members that enclose the building.

- Doors and windows: These are the openings in the wall panels that allow people and light into the building.

- Insulation: This is material that is used to reduce heat loss and gain in the building.

- Sheet metal: This is material that is used to cover the exterior of the building.

- Roofing: This is material that is used to cover the roof of the building.

- Siding: This is material that is used to cover the exterior walls of the building.