Custom Steel Conveyor Manufacturer

Custom Steel Conveyor Manufacturer

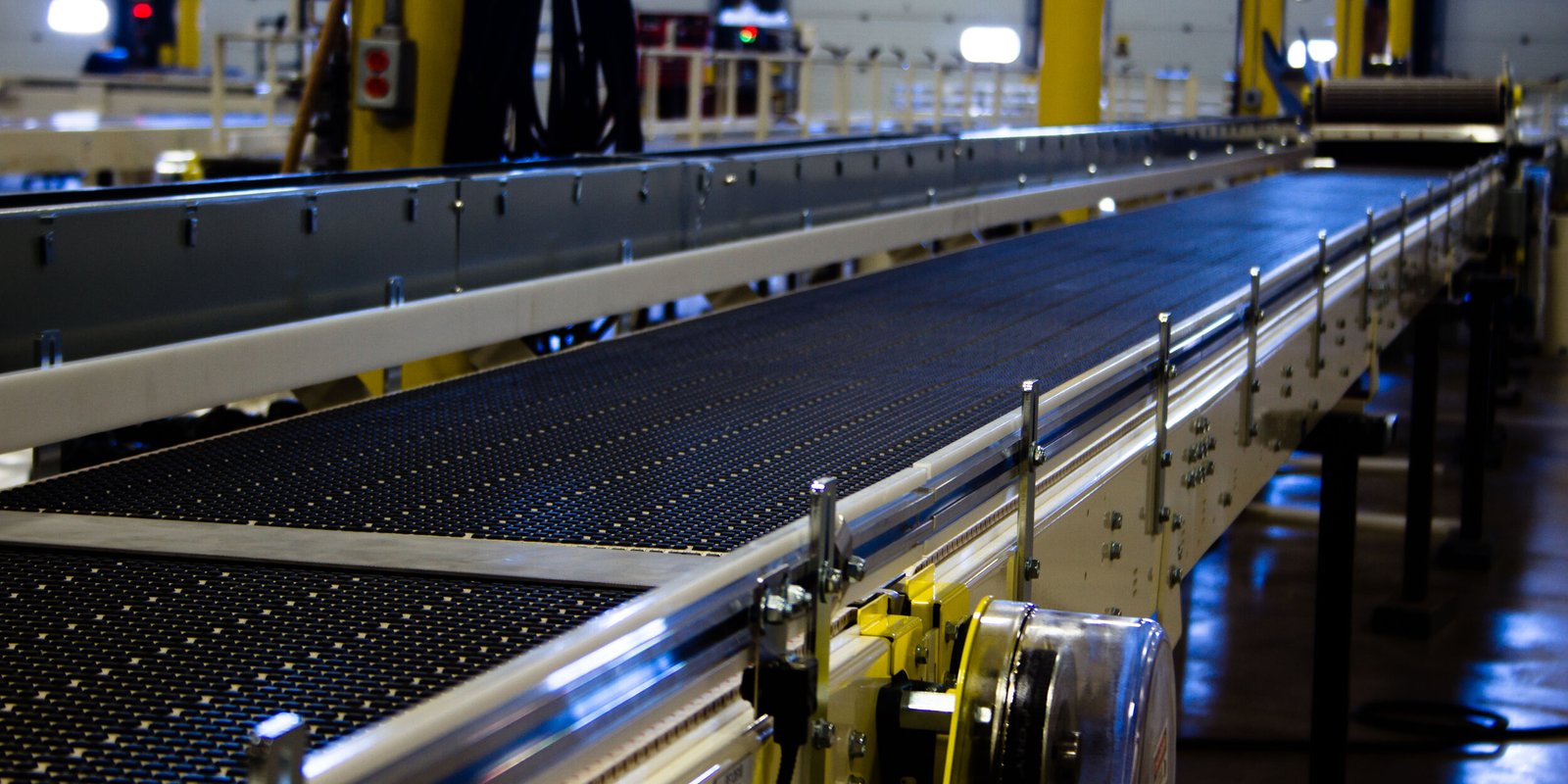

Custom steel conveyors are built for real-world industrial challenges—where reliability, hygiene, and long-term performance actually matter. At Sun Corporation, we design and manufacture custom steel conveyor systems that move materials smoothly, safely, and efficiently across diverse industries.

From food processing and pharmaceuticals to heavy manufacturing and logistics, our custom steel conveyors are engineered to match your exact operational requirements. We carefully consider load capacity, product flow, operating environment, and space constraints to deliver conveyor solutions that work consistently, shift after shift.

Our in-house metal fabrication expertise allows us to handle everything—from concept and design to fabrication, installation, and post-delivery support—ensuring complete control over quality and performance.

Benefits

Benefits

- Versatile by Design : Every operation is different, and so is every conveyor we build. Our custom steel conveyors can be manufactured in multiple sizes, layouts, and configurations, with optional rollers, chutes, guides, and bins to suit your workflow.

- Built for Durability : Steel offers exceptional strength and resistance to wear. Our conveyors are designed to handle heavy loads, continuous operation, and harsh industrial conditions without compromising structural integrity.

- Easy to Clean Maintain: Stainless steel conveyor systems are ideal for hygiene-critical environments such as food and pharmaceutical units. Smooth surfaces allow quick cleaning, sanitization, and pressure washing with minimal downtime.

- Cost-Effective Over Time : While designed for performance, our custom steel conveyors also deliver long-term value. Their robust construction reduces repair frequency and extends service life, lowering overall operational costs.

If you’re looking for a conveyor solution that balances strength, flexibility, and affordability, custom steel conveyors are a smart investment.

Components to Consider

Components to Consider

Every conveyor application demands a specific belt type and structural configuration. Based on your product characteristics and process flow, we offer several conveyor belt options:

- Smooth Surface Conveyor Belts : Ideal for stable product movement and easy maintenance, especially where liquids or fine materials are involved.

- Woven Wire Belts : Best suited for flexible applications requiring airflow, heat resistance, or direction changes without stressing the belt structure.

- Hinge Metal Belting : Designed to handle sharp, heavy, or high-impact materials while maintaining excellent load retention and durability.

- Cusped Conveyor Belts : Perfect for inclined movement and transporting small or moist items without spillage or slippage.

Each belt type is selected based on product size, weight, moisture level, and hygiene requirements to ensure smooth and uninterrupted operation.

Why Choose Sun Corporation?

Why Choose Sun Corporation?

With deep experience in structural steel fabrication and custom industrial solutions, Sun Corporation delivers conveyor systems that are engineered—not guessed. Our focus on quality materials, precise fabrication, and practical design ensures that every conveyor performs reliably in real operating conditions.

Get in touch today to discuss your custom steel conveyor requirements and discover a solution built specifically for your process—not a generic fit.