Pre-Engineered Steel Buildings (PEBs)

PEB

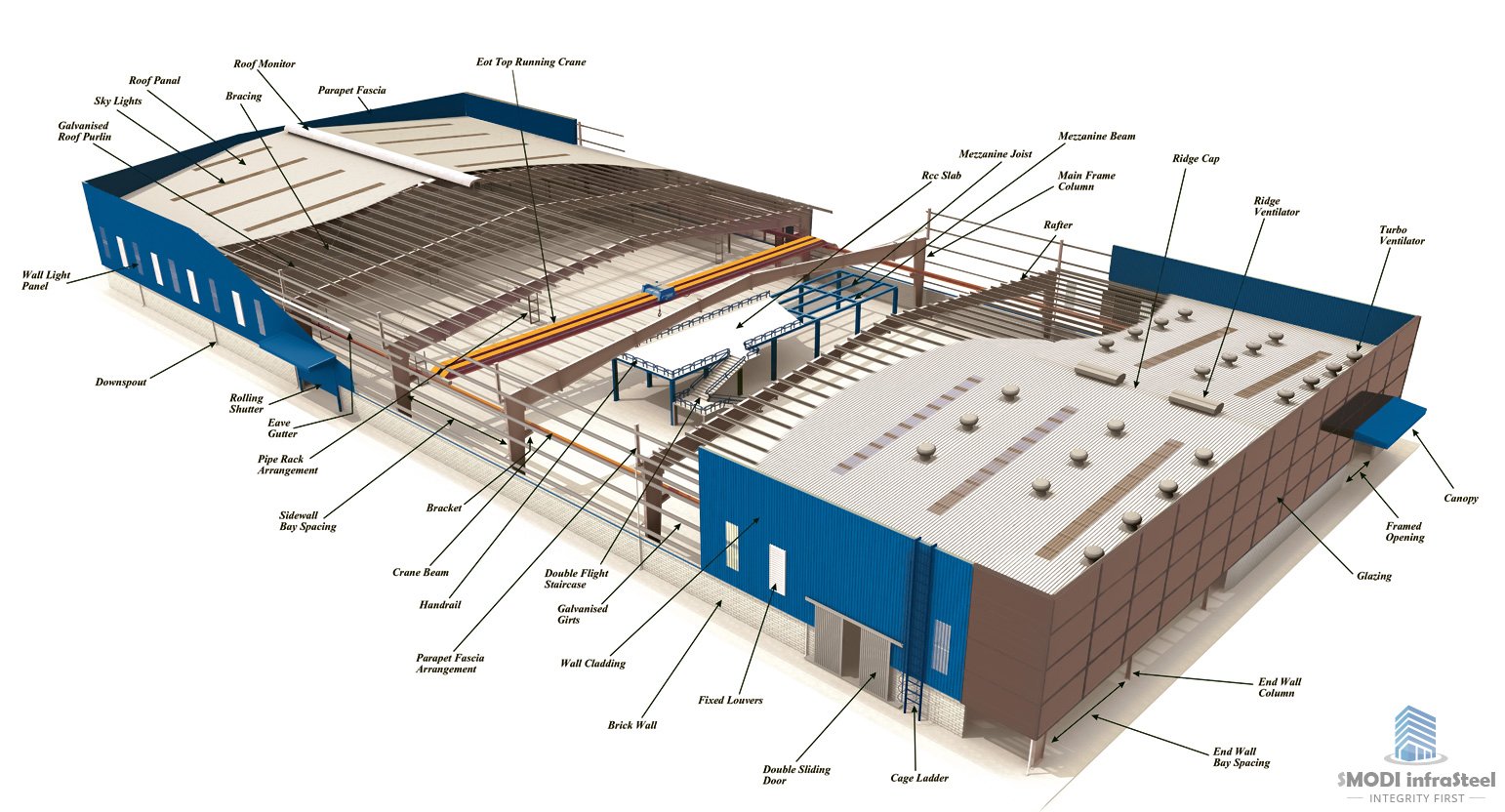

Pre-Engineered Steel Buildings (PEBs) are modern steel structures designed and manufactured using a system-based approach. These buildings are composed of primary members, secondary members, roof and wall sheeting, and are engineered to work as a single, integrated structure. Every PEB steel structure is custom-designed to meet specific project requirements, ensuring strength, efficiency, and optimal material usage.

PEBs can be easily integrated with both structural and non-structural elements such as skylights, ridge ventilators, turbo vents, louvers, cranes, mezzanine floors, canopies, insulation systems, doors, and windows. Over the last few decades, advancements in pre-engineered building design have significantly improved flexibility, durability, and adaptability—making steel one of the most preferred construction materials today.

Wide-span, low-rise, non-residential buildings are especially well suited for PEBs. With benefits such as faster execution, factory-controlled quality, long service life, and cost efficiency, PEB manufacturing has become a reliable solution for factories, warehouses, industrial sheds, showrooms, hangars, metro stations, commercial spaces, schools, hospitals, and community buildings.

As an experienced PEB solution provider, Sun Corporation Fabricators & Engineers offers end-to-end services covering design, fabrication, and erection—ensuring consistent quality control throughout the project lifecycle.

Components of Pre-Engineered Steel Buildings

Pre-engineered steel buildings consist of the following components:

Pre-engineered steel buildings consist of carefully engineered components that together ensure structural stability and long-term performance:

- Columns: Vertical structural members that transfer building loads safely to the

foundation. - Beams: Horizontal members that support roof and floor loads.

- Girders: Primary horizontal members that distribute loads to columns.

- Purlins: Secondary horizontal members supporting roof sheeting.

- Rafters: Inclined members that form the roof framework.

- Roof deck :The base surface on which roofing sheets are fixed.

- Wall panels: Enclosure elements that protect the building from external conditions.

- Doors and windows: Functional openings providing access, ventilation, and natural

light. - Insulation: Materials used to control heat gain and heat loss inside the building.

- Sheet metal: Exterior cladding used for wall and roof coverage.

- Roofing and Siding : Protective outer layers that enhance durability and aesthetics.

Advantages of PEB Structures

PEB structures offer multiple advantages over conventional construction methods. Factory-

controlled fabrication improves accuracy and reduces material wastage, while rapid installation shortens project timelines. Steel, being recyclable, makes PEBs an environmentally responsible

choice.

Additionally, steel’s high strength-to-weight ratio allows buildings to remain lightweight yet

exceptionally strong, resulting in reduced foundation loads and better seismic performance. These factors make pre-engineered steel buildings a cost-effective and durable solution for modern infrastructure needs.

Trusted PEB Manufacturing and Execution

Sun Corporation Fabricators & Engineers, a recognized PEB company in Hyderabad,

delivers reliable and customizable pre-engineered building solutions across India. From concept design to fabrication and erection, every stage is handled with technical expertise and strict quality standards.

With proven experience and a strong execution track record, we support clients looking for

efficient, scalable, and long-lasting steel building solutions.